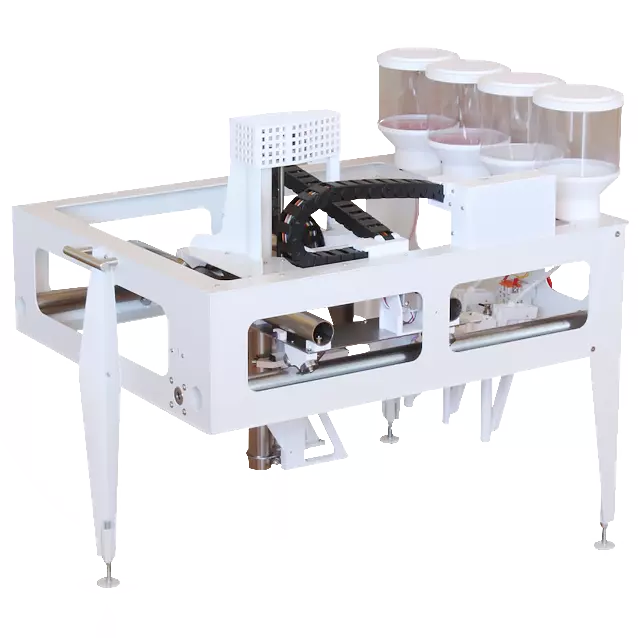

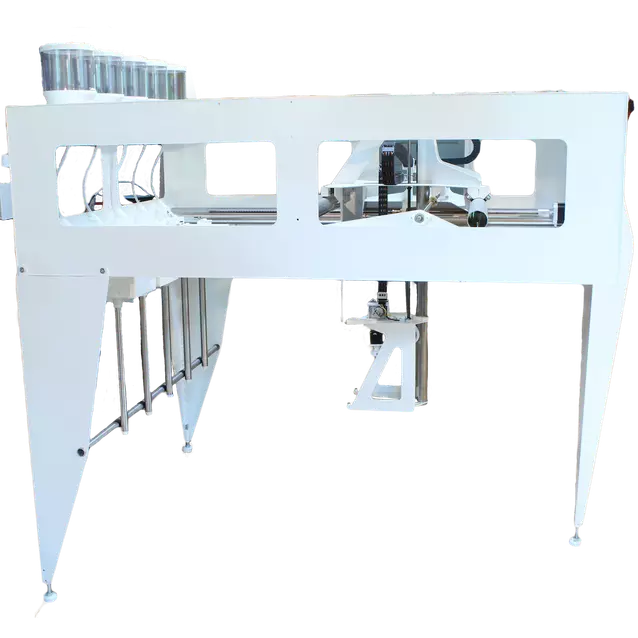

How Selective Powder Deposition works

Overview

Selective Powder Deposition (SPD) is a new 3D printing process, which you can use to print metal, glass,

ceramic, and composite materials.

There are 2 main variants: infilling and sintering.

With infilling you get a 100% solid object, and with sintering you usually get a porous object.

The best metal 3D printer video helps visualizing it.

Variant 1 - SPD with infill

First, the 3D printer selectively deposits build and support powders into a crucible.

When it finishes filling the whole crucible, you add some infill material, and bake it in a kiln.

The temperature in the kiln should be above the melting temperature of the infill, but below the melting temperature of the powders.

When the infill melts, it soaks the build powder, but it doesn't soak the support powder, because the support powder is chosen such that it's not wettable by the infill.

To prevent metal oxidation, the atmosphere in the crucible should be reducing.

The easiest way to create a reducing atmosphere is to place some carbon (metallurgical coke) or hydro-carbon (plastic) in the crucible.

But some metals require a controlled atmosphere furnace with hydrogen and argon.

After the infilling, if you cool down the crucible quickly - you'll get a composite material, because the atoms of the build powder and the infill didn't have enough time to mix.

But if you hold it at high temperature for a while - the atoms of the build powder and the infill will diffuse and mix with each other, so you'll get a uniform alloy.

The time required for diffusion depends on the metals and temperature. For example, at 790°C, copper+tin can mix uniformly in 2 hours and you'll get bronze.

But copper and tungsten, even at 1090°C, won't alloy much even in a day, so you'll get a composite.

When it cools down, remove it from the kiln, and clean it with a wire brush or sand blaster.

Variant 2 - SPD with sintering

The 2nd variant, sintering - is even simpler - you just don't add any infill, and bake it at the temperature sufficient to sinter the build powder.

Note that sintering causes shrinkage and warping.

By changing the baking temperature, you can influence the amount of shrinkage, warping and porosity.

With sintering it's hard to achieve 100% density with pure metals (those that have a single melting point), but it's easy with glass,

and some metal alloys, though it requires a vacuum furnace.

Materials

In theory, SPD can be used to 3D print almost any material. Actually, the printer itself is material

agnostic, and can pour any powder that flows through a small hole.

But when it comes to baking, some materials are easier than others.

For the details see Which materials can be 3D printed with SPD